Electronics Industry Solutions with High-Precision Metal Components

The electronics industry demands components that are not only reliable but also highly precise to ensure optimal performance in complex devices. Electronics Industry manufacturers increasingly rely on high-precision metal components to meet these stringent requirements. By integrating advanced manufacturing techniques, the electronics industry can produce parts with micron-level tolerances, consistent quality, and exceptional durability. High-precision metal components play a vital role in ensuring the efficiency, longevity, and safety of electronic devices, making them indispensable across consumer electronics, telecommunications, medical equipment, and industrial automation.

Importance of Precision in the Electronics Industry

Precision is critical in the Electronics Industry due to the miniaturization of devices and the complexity of modern electronic systems. Small deviations in dimensions can cause malfunction, poor connectivity, or reduced lifespan of components. High-precision metal components, including connectors, enclosures, heat sinks, and shielding elements, ensure that each part fits perfectly and performs reliably under electrical, thermal, and mechanical stress.

Manufacturers in the electronics industry benefit from precision engineering because it reduces assembly errors, enhances product performance, and supports innovative designs. Components with exact specifications contribute to improved signal integrity, thermal management, and structural stability in devices ranging from smartphones to industrial sensors.

Materials and Manufacturing Techniques

The electronics industry requires components made from metals that offer excellent conductivity, corrosion resistance, and strength. Commonly used metals include aluminum, copper, brass, stainless steel, and specialized alloys. Each material is selected based on its electrical, thermal, and mechanical properties to ensure optimal functionality within electronic assemblies.

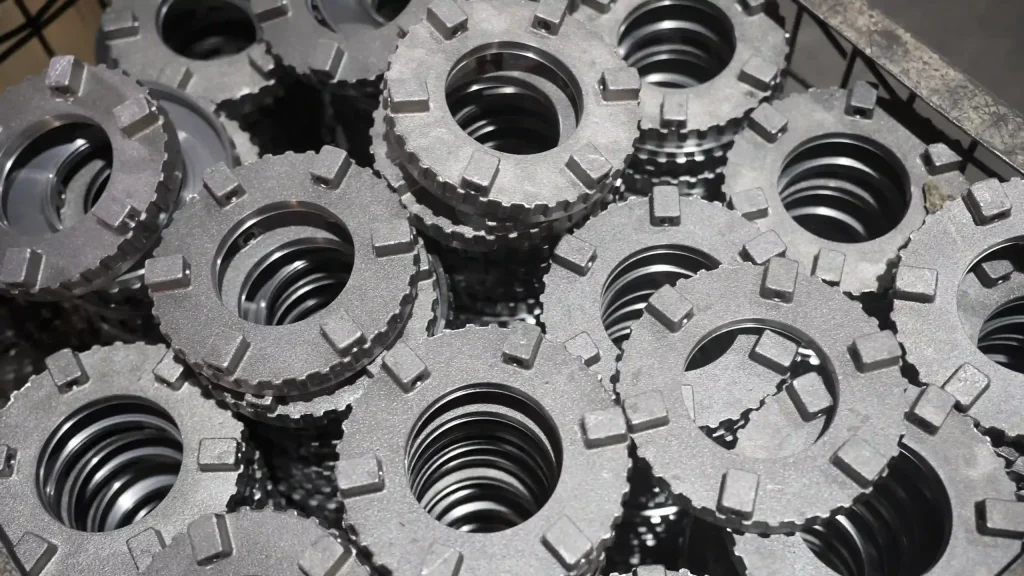

Advanced manufacturing techniques such as CNC machining, die casting, stamping, and additive manufacturing are employed to produce high-precision metal components. These processes enable tight tolerances, smooth finishes, and repeatable quality, which are essential for the electronics industry. By combining skilled engineering with cutting-edge equipment, manufacturers can produce components that meet the demanding standards of the industry.

Applications in Modern Electronics

High-precision metal components are widely used in various segments of the electronics industry. In consumer electronics, metal enclosures and frames provide protection and structural support for devices like laptops, tablets, and smartphones. Connectors and terminals ensure reliable electrical connections and signal transmission. Heat sinks, often made from aluminum or copper, manage thermal loads and prevent overheating, which is crucial for device longevity and performance.

In telecommunications, high-precision components support antennas, switches, and circuit boards that require exact alignment and consistent electrical performance. In medical electronics, components must meet strict regulatory standards while providing high accuracy and reliability, as they are often used in critical diagnostic and therapeutic equipment. Industrial electronics also rely on metal parts for robust performance in harsh environments, including automation systems and control panels.

Quality Control and Reliability

The electronics industry emphasizes rigorous quality control to maintain reliability and compliance with industry standards. High-precision metal components undergo thorough inspection, including dimensional verification, surface finish assessment, and material property testing. This ensures that every part meets design specifications and can withstand operational stresses without failure.

Reliable components contribute to the overall quality of electronic products, reducing returns, downtime, and maintenance costs. By implementing robust quality assurance processes, manufacturers in the electronics industry can deliver components that consistently perform to specification, enhancing device efficiency and user satisfaction.

Advancements and Innovation

The electronics industry continues to evolve, with increasing demand for miniaturization, higher performance, and energy efficiency. High-precision metal components enable innovation by allowing complex geometries, tight tolerances, and specialized materials to be incorporated into designs. Advanced fabrication technologies such as micro-machining and additive manufacturing are being adopted to meet these evolving requirements.

Manufacturers that leverage high-precision components can offer solutions that are lighter, more compact, and more efficient, supporting the development of next-generation electronics. This capability is essential for maintaining a competitive edge in an industry where technological advancement occurs rapidly.

Choosing the Right Partner for High-Precision Components

Selecting a reliable manufacturing partner is crucial for producing high-precision metal components for the electronics industry. The ideal partner should have expertise in materials, advanced machining capabilities, and robust quality assurance systems. Collaboration with experienced manufacturers ensures that components meet both functional and regulatory requirements while optimizing production efficiency.

A trusted partner also provides support in design optimization, prototyping, and post-production finishing, helping electronics industry clients achieve high-quality results with minimal risk of defects or delays.

FAQs Leierwo

Why are high-precision metal components important in the electronics industry?

They ensure accurate fit, reliable performance, thermal management, and durability in electronic devices and systems.

What materials are commonly used for metal components in electronics?

Aluminum, copper, brass, stainless steel, and specialized alloys are commonly used due to their electrical, thermal, and mechanical properties.

Can high-precision components be customized for specific electronic applications?

Yes, manufacturing techniques allow for tailored geometries, tight tolerances, and specialized material properties to meet unique requirements.

Which sectors benefit most from high-precision metal components in electronics?

Consumer electronics, telecommunications, medical electronics, and industrial automation all rely on high-precision metal components for performance and reliability.