Introduction to Metal Manufacturing in Edmonton

In the heart of Alberta, the city of Edmonton serves as a hub for numerous industries, including metal manufacturing. This vibrant sector plays a vital role in supplying necessary components and materials for a vast range of applications, from construction to aerospace engineering. Understanding the intricacies of metal manufacturer edmonton is essential for businesses looking to harness these resources effectively.

Understanding Metal Manufacturer Edmonton

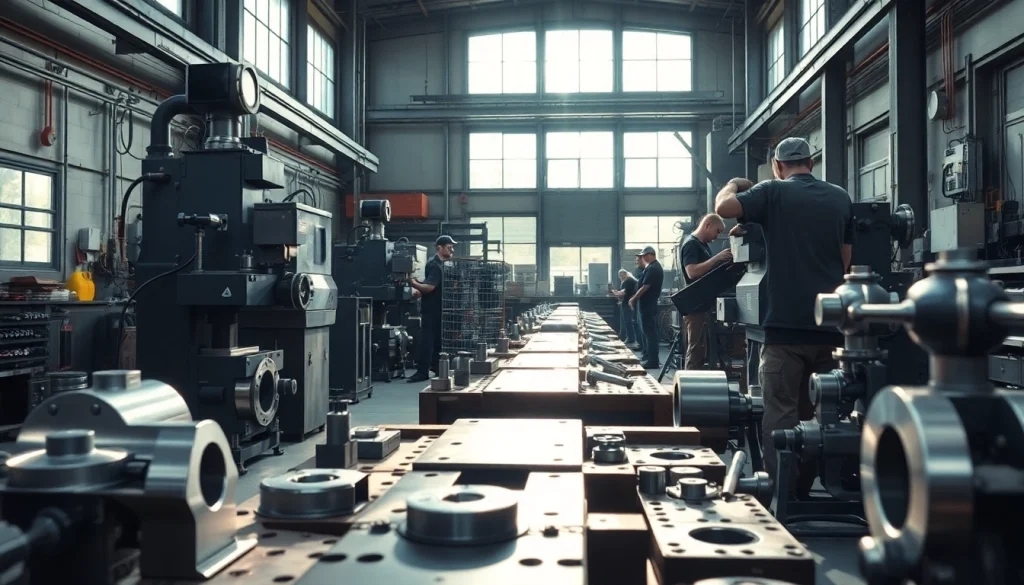

Metal manufacturing in Edmonton encompasses various processes involved in shaping and assembling metal components. Manufacturers in this region have access to state-of-the-art technology and skilled personnel, enabling them to produce high-quality products tailored to the specific requirements of their clients. From industrial machinery parts to art installations, the versatility of metal fabrication is evident across multiple sectors.

Importance of Local Metal Fabrication Services

Local metal fabrication services are critical for businesses that require prompt solutions and customized products. Utilizing a nearby metal manufacturer not only reduces shipping times and costs, but also fosters collaboration between engineers and fabricators. Clients can visit facilities, inspect production capabilities, and engage in hands-on discussions—an invaluable aspect for ensuring project specifications are met efficiently.

Types of Metals Commonly Used

The choice of metal can significantly influence the performance and longevity of a product. Common metals utilized in manufacturing processes within Edmonton include:

- Steel: Known for its strength and versatility, steel is a go-to choice for construction, automotive, and machinery applications.

- Aluminum: Lightweight and resistant to corrosion, aluminum is favored in aerospace and transportation sectors.

- Brass: This alloy of copper and zinc is valued for its thermal and electrical conductivity, making it ideal for electronics and plumbing fixtures.

- Copper: With its excellent electrical and thermal conductivity, copper is often used in electrical wire and thermal systems.

Choosing the Right Metal Manufacturer Edmonton

Selecting a reliable metal manufacturer is a pivotal step in any engineering project, where various factors need to be evaluated to find the best fit.

Key Factors in Selecting a Metal Fabricator

When choosing a metal manufacturer in Edmonton, consider factors such as:

- Experience: Look for a manufacturer with a proven track record in the industry, as their expertise can greatly influence project success.

- Specialization: Assess whether the fabricator specializes in the particular type of metal or project requirements you have.

- Certification: Ensure that the manufacturer holds relevant certifications, signifying adherence to industry standards and best practices.

Evaluating Fabrication Capabilities

Understanding the fabrication capabilities of the manufacturer is crucial. Key aspects to evaluate include:

- Machinery and Technology: Inspect the types and sophistication of the machinery employed in the manufacturing process.

- Production Volume: Determine whether the manufacturer can meet your production needs, whether it be low volume custom work or large-scale production.

- Lead Times: Inquire about lead times and production schedules to ensure they align with your project timelines.

Assessing Customer Reviews and Testimonials

Reading customer reviews and testimonials provides insight into a manufacturer’s reliability and quality of service. Check platforms dedicated to business reviews, but also seek out case studies that detail past projects. This will give you a deeper understanding of the fabricator’s strengths and how they handle challenges.

Common Services Offered by Metal Manufacturers Edmonton

Metal manufacturers in Edmonton provide a range of services that cater to diverse client needs.

Custom Metal Fabrication Solutions

Custom metal fabrication is a hallmark of many manufacturers in Edmonton. This service involves designing and building components tailored to precise specifications, allowing businesses to address unique challenges and requirements. Whether it’s creating intricate designs or producing functional parts, custom solutions provide flexibility in meeting individual project demands.

Welding and Assembly Services

Welding is a fundamental service offered by metal manufacturers, essential for joining metal parts together. Competent welders use various techniques, such as MIG, TIG, and spot welding, to ensure strong and durable joints. Assembly services may also be available, where manufacturers combine various components into a finished product, streamlining the supply chain for clients.

Metal Finishing Techniques

Finishing techniques are vital for enhancing the durability and aesthetic appeal of metal products. Common methods include:

- Powder Coating: A dry finishing process that provides a protective layer while offering various color options.

- Anodizing: Mostly used on aluminum, this electrochemical process improves corrosion resistance and surface hardness.

- Polishing: Enhances the surface finish and provides a reflective quality, particularly on stainless steel.

Trends in Metal Manufacturing Edmonton

The landscape of metal manufacturing is constantly changing, influenced by advancements in technology, economic conditions, and evolving customer expectations.

Emerging Technologies in Fabrication

Advanced technologies such as computer numerical control (CNC) machining and additive manufacturing (3D printing) are revolutionizing the industry. CNC technology allows for precise and consistent production, while 3D printing is reshaping design possibilities, enabling manufacturers to create complex geometries and reduce material waste.

Sustainability Practices in Metal Manufacturing

Sustainability is increasingly becoming a focal point in the metal manufacturing sector. Manufacturers are adopting practices such as recycling scrap materials, using energy-efficient machinery, and sourcing sustainable materials. These initiatives not only reduce environmental impact but also appeal to eco-conscious consumers and businesses.

Industry Innovations Shaping the Future

Innovations like the Internet of Things (IoT) and artificial intelligence (AI) are enhancing operational efficiency. IoT devices can offer real-time monitoring of equipment, allowing for predictive maintenance and minimizing downtime. AI can optimize production schedules and streamline supply chains, dramatically improving responsiveness and efficiency in manufacturing processes.

FAQ Section

What types of metals do manufacturers in Edmonton work with?

Manufacturers typically work with steel, aluminum, brass, and copper, based on project needs.

How do I choose a reliable metal manufacturer Edmonton?

Check their portfolio, customer feedback, capabilities, and experience in specific projects.

Are custom metal fabrication services expensive?

Costs can vary widely, but custom solutions often save money in the long run by meeting precise needs.

How quickly can orders be fulfilled?

Order fulfillment times depend on complexity; basic orders can be fulfilled in days, while custom projects may take longer.

Do metal manufacturers offer design assistance?

Many manufacturers provide design assistance to ensure optimal results for your specific metal fabrications.